Product Introduction

Ablyy's width gauge uses binocular vision technology and can measure the width of materials such as carbon steel, stainless steel, aluminum plates, and copper plates. This device measures using 2 or 4 industrial CMOS line-scan cameras according to the plate width and can output data such as hot-state width, cold-state width, and centerline deviation. Currently, it has been widely applied in domestic and international hot continuous rolling, medium and heavy plate, cold rolling, and other production lines. For hot rolling production lines, when the strip steel temperature is higher than 800 degrees Celsius, it uses the infrared measurement principle for measurement; for cold processing lines, when the material temperature is low, it uses backlighting or top lighting for measurement.

Product Advantages

♦ High-Speed FPGA Module: Features a high-speed industrial data processing module based on FPGA, ensuring fast sampling and stable, accurate data.

♦ Binocular Vision Compensation: Uses binocular vision technology to effectively identify and compensate for vibration, inclination, and lateral deviation of the measured steel plate.

♦ Dynamic Parameter Compensation: Automatically compensates for steel plate temperature, material, and thickness in real time.

♦ Cold-State Width Calculation: Computes and displays cold-state width dynamically based on material parameters.

♦ Advanced Sensor Technology: Utilizes international-grade CCD sensors and a custom-developed high-speed DSP acquisition circuit with technologies like non-uniform linear correction, fixed-image noise reduction, electronic exposure, correlated double sampling, dual exposure, and intelligent model learning to enhance accuracy and reliability.

♦ Dust/Waterproof Design: Professional purging system minimizes interference from water vapor and dust.

♦ Low-Maintenance System: All-digital architecture with automatic calibration and intelligent self-diagnosis reduces maintenance workload.

♦ Dual-Target Calibration: Advanced dual-target calibration eliminates measurement errors caused by lens distortion, plate tilt, or vibration.

♦ User-Friendly Calibration: "Wizard-style" calibration interface simplifies and visualizes the width calibration process.

♦ Customizable Features: High-end configuration allows optional upgrades like optimized shearing or hole/edge crack detection.

♦ Flexible Connectivity: Supports multiple communication interfaces (e.g., Ethernet) with customizable protocols to meet user needs.

Application Showcase

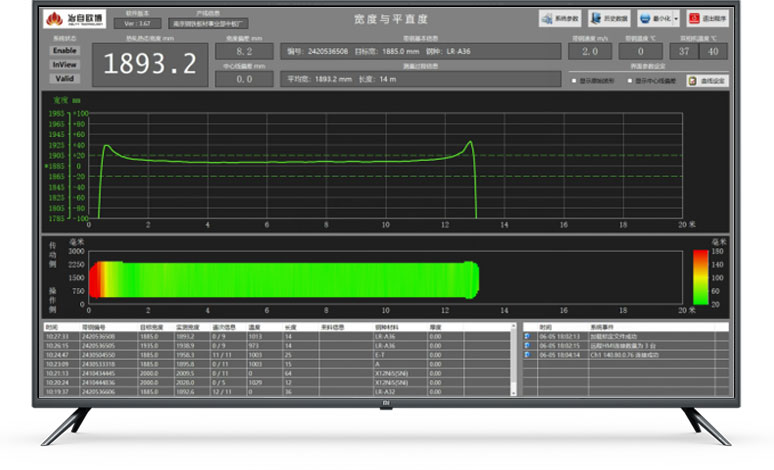

System Interface