Product Introduction

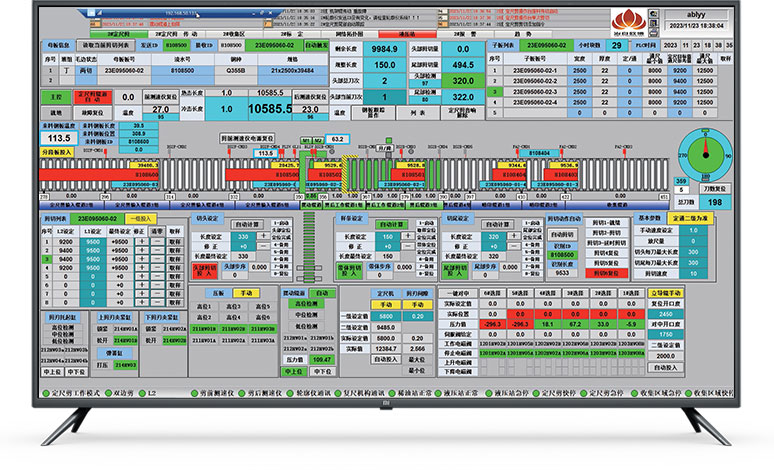

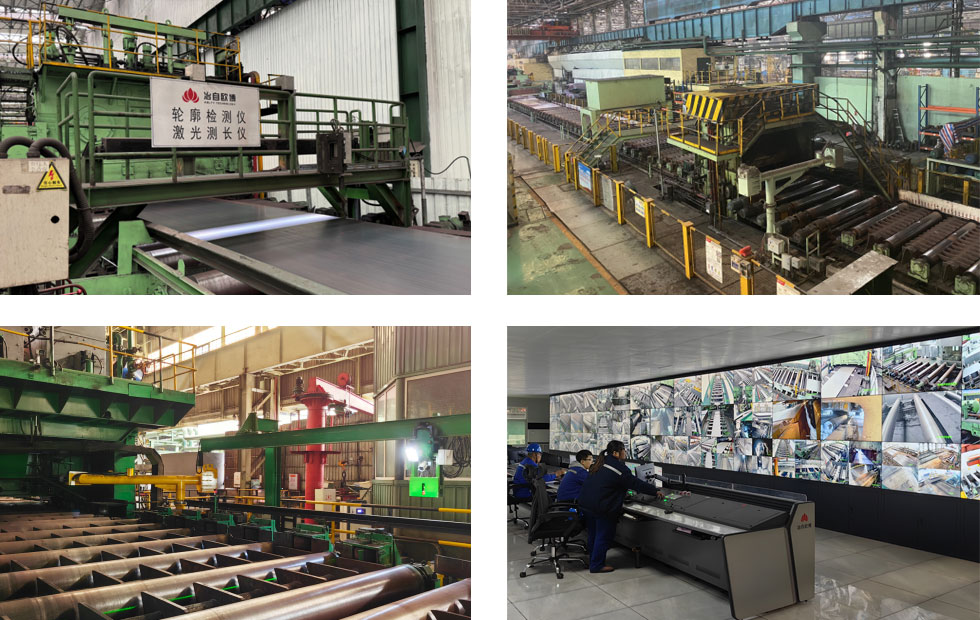

♦ Intelligent Cutting Optimization System for Heavy plate in Plate cutting area:The intelligent cutting optimization system for heavy plates is designed to track the position of steel plates throughout the entire process, from the roller table of the hot straightening exit to the roller table after the cutting, head cutting, and fixed-length cutting. By adding cold metal detector, laser speed &length gauge, profiling gauge, and other testing devices, the control system is upgraded to enhance the cutting accuracy and efficiency in this area then realizes intelligent cutting optimization across the entire finishing line and improving material yield.

♦ Material Tracking System on Heavy Plate Production Line:Material tracking system on heavy Plate Production Line is the prerequisite and foundation for fully automated rolling. The tracking range spans from the heating furnace loading area to the finished product unloading (including the heating furnace area, rolling mill area, cooling area, hot straightening area, cooling bed, shearing area, and cutting-to-length area). It accurately tracks the position of steel plates on the production line and implements real-time database management of production data, used for model system calculations and model self-learning to improve control accuracy. This system provides production scheduling with an overview of the entire line production, facilitates smooth communication across departments, enhances production efficiency, and serves as the data foundation for subsequent quality analysis, quality dispute traceability, production statistics and management. It eliminates the digital gap between basic process automation and the MES management information system, avoiding "automation islands" and ensuring seamless data integration and effective information sharing.

Product Advantages

♦ Short Modification Time & Minimal Impact: Retrofit implemented on the existing control system ensures a short modification period and minimizes production disruption.

♦ Improved Productivity: Ablyy’s proprietary intelligent shearing control system enables automatic length measurement, automatic sizing, and automatic shearing, effectively enhancing production automation, reducing operator workload, and improving production line efficiency.

♦ Turnkey Solution: All intelligent instruments and control systems are self-developed and integrated by Ablyy, providing clients with a comprehensive turnkey project.

Application Showcase

System Interface