Product Introduction

The rolling mills of modern bar, wire rod and section steel production lines integrate high-speed rolling and automatic control technologies, raising production efficiency to a new level. Combining with these technological characteristics, Ablyy has transplanted the mature control technologies in the field of the three-electric intelligent control system of some high-quality hot-rolled strip steel production lines to the fields of bar, wire rod and section steel, and has developed advanced control technologies such as full-process micro-tension control, optimized shearing, intelligent micro-tracking, and rapid loop closed-loop control through secondary development, which have been successfully applied.

1. Electrical Drive System: Complete sets of electrical drive systems for the entire production line, including motor, transformer, high/low voltage, reactive power compensation, and AC/DC electrical drive system design, supply, and commissioning.

2. Basic Automation System: Design, supply, and on-site commissioning of the basic automation system for the entire production line.

3. Process Control System: Design, supply, and on-site commissioning of the process automation system for the entire production line, primarily focusing on storage, download, and automatic optimization of rolling schedule tables, as well as management of rolling plans and reports.

4. Rolling Line Instruments: Design, supply, and on-site commissioning of instrument systems such as loop scanners, hot detection, cold detection, and temperature measurement for the entire production line.

Product Advantages

♦ Short Project Cycle: Rapid system implementation and commissioning. After equipment installation, trial rolling can start in as fast as 2–3 days, ensuring a successful first pass and fine-tuning completion within half a month.

♦ Stable Performance & High Accuracy: Reliable, stable control systems with low failure rates, meeting full user requirements for precision.

♦ Premium After-Sales Service: Equipped with self-developed PDA high-speed data acquisition system and remote monitoring system for 24/7 remote technical support. Committed to on-site technician arrival within 24 hours if needed.

Application Showcase

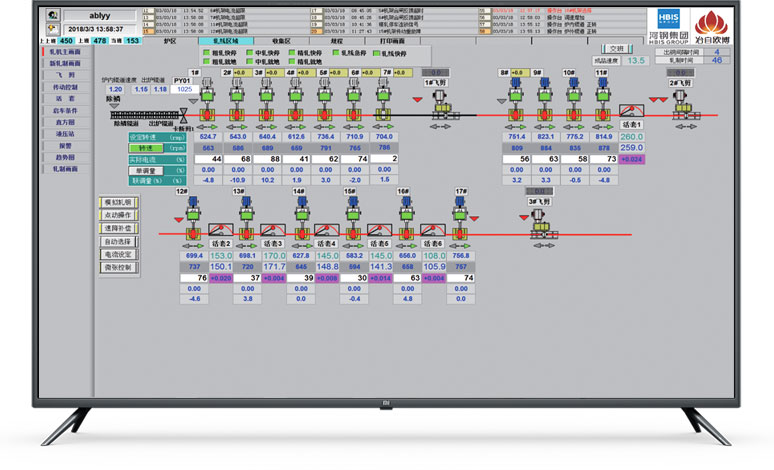

System Interface