Product Introduction

Ablyy’s Flatness Detection System is an on-line inspection equipment using dual laser line measurement technology. The dual laser line design accurately captures surface irregularities while effectively canceling out vibration-induced surface fluctuations, enabling precise calculation of the true 3D profile of the measured material. Based on this, the system simultaneously measures both flatness and width, providing comprehensive inspection data. Suitable for hot rolling, cold rolling, leveling, and skin-pass production lines, it offers high precision and speed for both final product inspection and closed-loop leveling control.

Product Advantages

♦ Non-Contact Measurement: Uses optical sensors to eliminate mechanical wear and ensure long-term reliability.

♦ Automated Flatness Grading: Automatically detects flatness and grades products to reduce scrap rates and improve quality.

♦ Fully Automated Operation: Real-time on-line measurement minimizes manual labor and enhances operator safety.

♦ High Efficiency & Cost-Effectiveness: Combines high precision with a simple, low-cost system structure.

♦ Data Traceability: Provides recording and archiving capabilities for full quality traceability.

Application Showcase

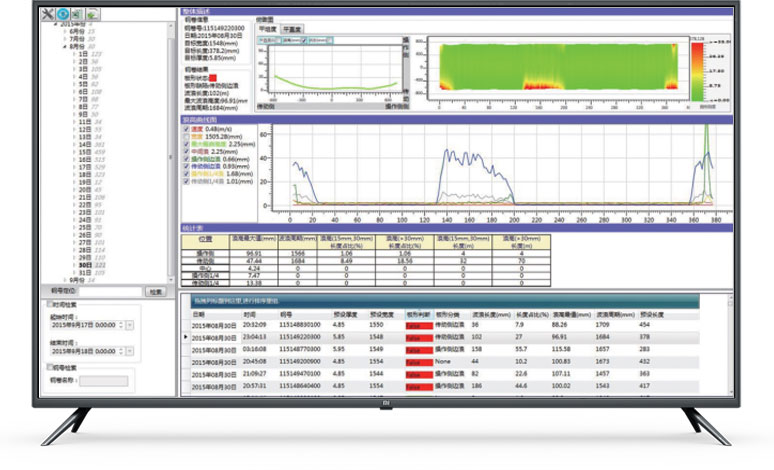

System Interface