Product Introduction

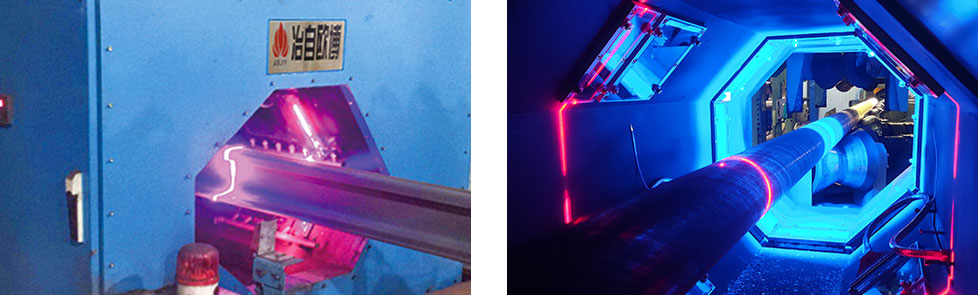

In the production of steel pipes, rails, H-beams, square pipes, angle steel, and angle bars, changes in defect opening on the surface can significantly impact overall product quality. Ablyy’s self-developed on-line 3D surface defect and profile inspection system empowers production managers to overcome the challenge of incomplete surface quality monitoring. This system combines line laser and ultra-high-speed area array cameras to reconstruct 3D surface information and calculate profile dimensions of sections, enabling comprehensive 3D surface defect and dimensional inspection for shaped steel.

Product Advantages

♦ High Efficiency & Speed:

Utilizes internationally advanced high-speed cameras for 360° full-view surface inspection of workpieces in seconds, drastically improving detection efficiency.

Automates inspection workflows through automated equipment and software, reducing manual intervention and labor costs.

Provides real-time results to enable immediate production adjustments and quality control.

♦ Precision & Reliability:

Achieves sub-millimeter measurement accuracy with 3D surface detection technology, capturing even 微小 defects.

Rigorously tested and validated to ensure consistent accuracy and reliability, minimizing defective product rates.

Conducts thorough inspections of all workpiece areas to eliminate missed or false detections.

♦ Flexibility & Adaptability:

Applies to diverse workpiece types and surface materials, including steel, aluminum, and composites.

Offers customizable inspection solutions tailored to specific customer needs and industry requirements.

Seamlessly integrates with existing production equipment and systems for 智能化 and automated workflows.

♦ Advanced Intelligence:

Incorporates cutting-edge deep learning algorithms to continuously enhance defect detection capabilities.

Uses big data analytics for intelligent interpretation of results, providing actionable quality insights and improvement recommendations.

Enables predictive maintenance by analyzing historical and real-time data to identify and address potential issues proactively.

Application Showcase